Contract Manufacturing

Tailored for startups and growth-stage companies, our contract manufacturing expertise spans from verification & pilot builds to large-scale production, offering seamless scalability and dedicated support.

State-of-the-art Finished Goods Assembly Facilities

ISO 13485 certified

FDA registered facility

Class 7 clean room

Fast, flexible, and specialized for startups and growth-stage companies

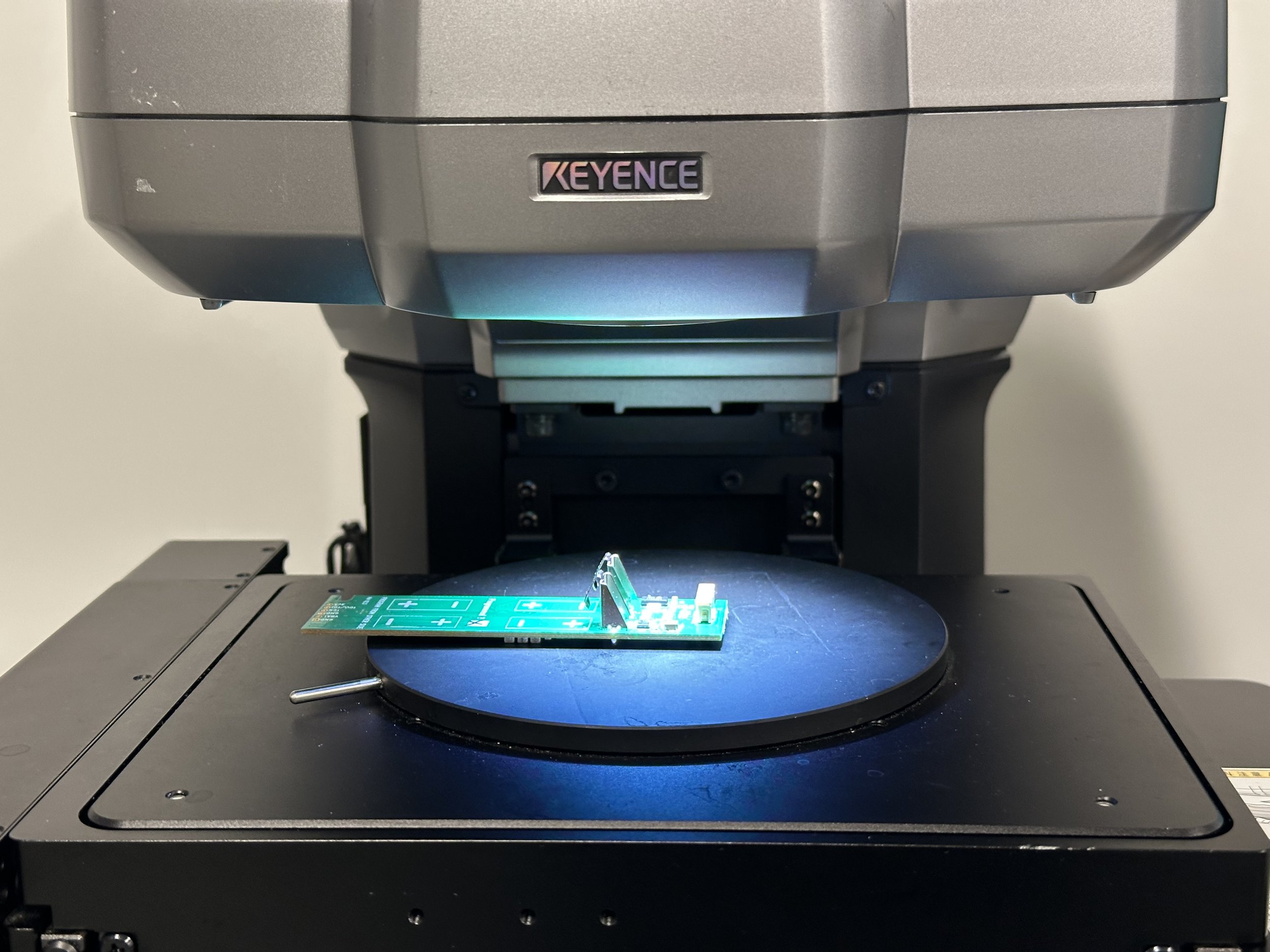

Manufacturing Capabilities

-

Process Development

-

Process Validation

-

Supply Chain Management

-

Metrology

-

Device Assembly

-

Ultrasonic Welding

-

Laser Welding

-

Soldering

-

3D Printing

-

UV Curing / Adhesive Bonding

-

Sterile Pouch Sealing

-

Kitting & Secondary Packaging

-

Device Labeling

-

Thermoform Tray Sealing

-

Sterilization Coordination

Single Use / Sterile Devices

Catheters & Access devices

IV Sets & Fluid Delivery

Dialysis Consumables

Airway Management products

Electrsurgical Accessories

Infusion & Irrigation systems

Diagnostic consumables

Durable Equipment

Mobile Carts & Workstations

Ultrasound / Imaging carts

ECG / Diagnostic Testing Equipment

Electrosurgical Units (ESUs)

Fluid Management Systems

Electrsurgical Accessories

Infusion & Irrigation systems

Electromechanical Devices

Infusion Pumps

Patient Monitors

Wearable Medical Devices

Diagnostic Instruments

Neurostimulation Devices

CPAP/BiPAP & Respiratory Devices

Implantable Devices

Cardiac Devices

Neurological / Intracranial Devices

Subdermal implants

Cochlear Implants

Orthopedics

Seamless integration drives success.

Our manufacturing team collaborates closely with our design and engineering teams during product development. By integrating production considerations early in the design process, we achieve higher quality products and expedite the transition to manufacturing. Once in production, our engineering team remains available for ongoing product support and enhancements.

FREQUENTLY ASKED QUESTIONS

-

Quality is our top priority. We employ rigorous quality control measures, including ISO 13485 standards, in-line inspections, process validation, and final quality checks, to ensure every product meets the highest standards.

-

Absolutely. Our facilities are equipped to manage both small-scale pilot runs and large-volume production runs, ensuring scalability and flexibility for our clients. Whether you need 10 or 10,000, we can meet your needs.

-

Our agile manufacturing process allows for flexibility in design changes and order volumes, ensuring that we can quickly adapt to your needs while minimizing disruptions.